JIANGSU MITTEL STEEL INDUSTRIAL LIMITED

Jiangsu Mittel Steel Industrial Limited is located in Wuxi

City, a beautiful city near Shanghai. Wuxi is close to

Shanghai (BAO STEEL) ,Zhangjiagang (ZPSS),Ningbo (BAO

XIN),KUN SHAN (DKSS), enjoy excellent geographic location and

convenient water, land and air transportation. , Wuxi become

the biggest stainless steel sheet ,plate and coil

supply Centers in China. Jiangsu Mittel Steel Industrial

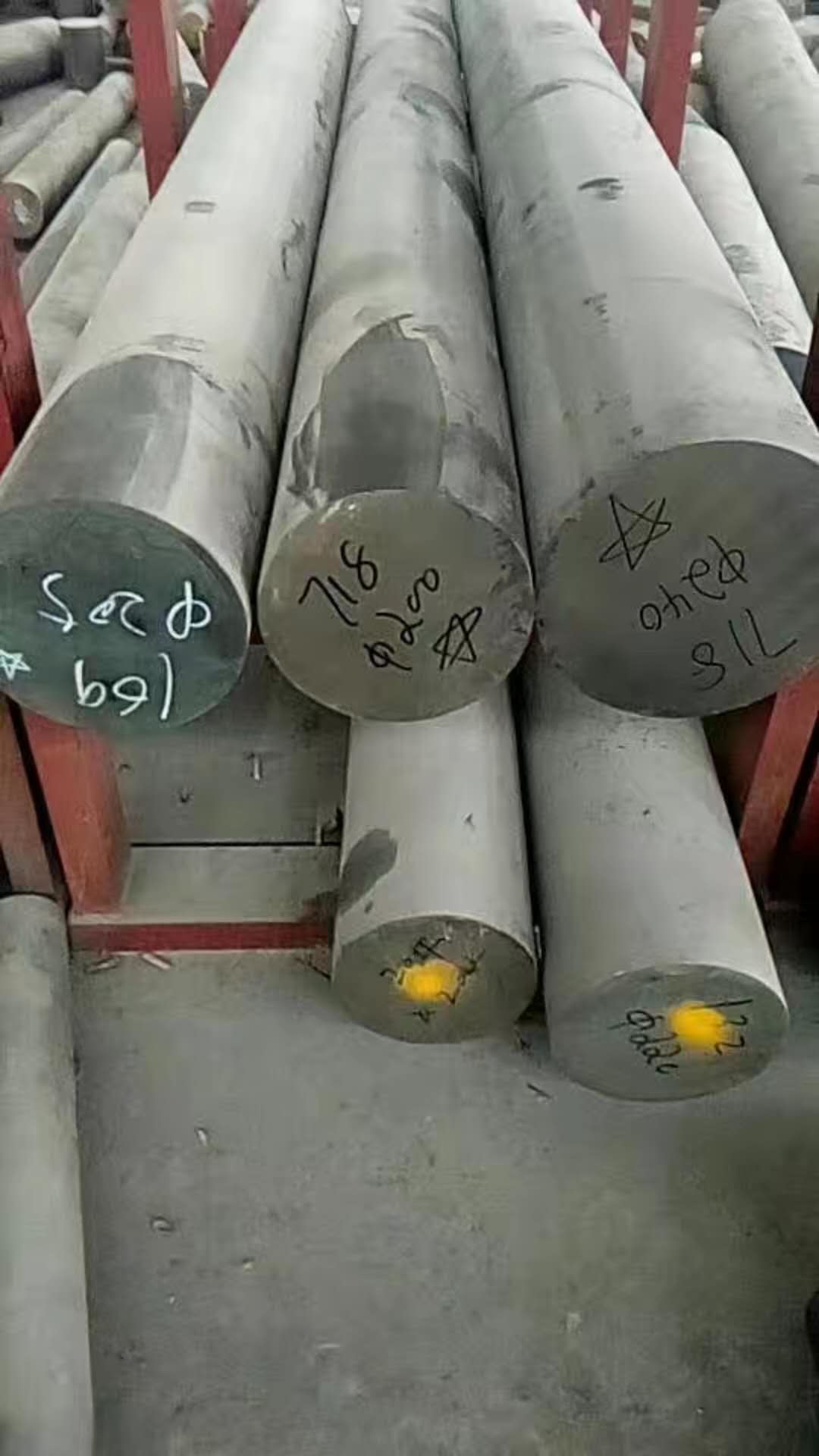

Limited was established in 1998 years. as one of the largest

stockists and manufacturers of industrial grade Stainless Steel

products and derivatives in Wuxi ,We keep a stock of 50000 tons

every month, so we can delivery goods in fast time.

Our company supplies cold/hot-rolled stainless steel

sheets,stainless steel coils and stainless steel Plate to many

steel factories from athome and abroad, including Shanxi Taigang

Iron& Steel CO, . Ltd (TISCO)Zhangjiagang Pohang (ZPSS), Shanghai

BAO STEEL, Ningbo Baoxin and steel factories in Taiwan area,

Mainland Chinese and foreign countries and regions.

Our long-term business lines are

201.202.304(1.4301).304L.316.316L(1.4404).430.409L, 309S

,310S(1.4845).317L.904L.S31803(1.4462).S32750.S32760, Finish: 2B,

BA, NO. 1 NO. 4, HL, 8K and so on...Meanwhile, our company is also

engaged in the long-term supply of homemade & imported medium and

thick plates, galvanized and carbon steel products.

Adhering to the principle of "quality first and customer

foremost",our company will offer long-term service to nationwide

manufacturers of household appliances, elevators, tableware,

ornaments, tanks and machines. We can offer precise frosted

wiredrawing, 8K mirror finishing and skim board oil-abrasion of

various specifications at any time. The precisely-processed

products will meet your requirements for high quality. Our company

is a modern enterprise integrating distribution and storage.

If you are interested in any of our products or would like to

discuss a custom order, please feel free to contact us. We are

looking forward to forming successful business relationships with

new clients around the world in the near future.